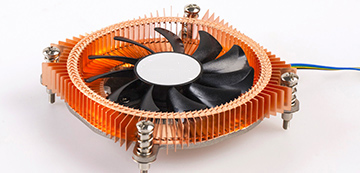

Radiator is a general term for a series of devices used to conduct and release heat. Radiators mainly include heating radiators and computer radiators. Heating radiators can be divided into several types according to material and working mode, and computer radiators can be divided into several types according to purpose and installation method. The production process of radiator is here.

1、 For the mold with high dense teeth and large tongue ratio, the first aluminum rod must be 150-200mm short aluminum rod or pure aluminum rod.

2、 Before die test, the extrusion center must be adjusted, and the extrusion shaft, ingot cylinder and die base outlet are on the same center line.

3、 In the process of mold test and normal production, the heating temperature of aluminum rod shall be guaranteed to be between 480-520 ℃.

4、 The mold heating temperature shall be controlled at about 480 ℃ according to the conventional mold temperature. The holding time of flat mold with diameter less than 200mm shall not be less than 2 hours. In case of shunt mold, the holding time shall be more than 3 hours; The mold with a diameter greater than 200mm shall be kept warm for 4-6 hours to ensure the uniformity of the core temperature and the external temperature of the mold.

5、 Before mold test or production, the cylinder cleaning pad must be used to clean the inner tank of ingot cylinder, and check whether the empty operation of extruder is normal.

6、 When testing the die or just starting production, the automatic gear of the extruder is turned off and the switches of each section are reset to zero. Slowly start from the minimum pressure and discharge for about 3-5 minutes. The pressure is mainly controlled during the aluminum filling process. The pressure shall be controlled within 100kg / cm2, and the ammeter data shall be within 2-3a. Generally, 80-120kg / cm2 can be discharged, and then it can be slowly accelerated. During normal production, the extrusion speed shall be subject to the pressure less than 120kg / cm2.

7、 In the process of mold trial or production, in case of mold blocking, tooth deviation, too large speed deviation and other phenomena, the mold shall be stopped immediately, and the mold shall be unloaded in the way of point return to avoid scrapping of the mold.

8、 In the process of mold test or production, the discharge port must be unobstructed, and the pad support or clamp looseness shall be reasonably controlled according to the discharge situation. Observe any abnormal situation at any time and deal with it in time. Stop the machine immediately when it is stopped.

9、 In the process of straightening, carefully detect the changes before and after, operate in a standardized manner, apply appropriate force, and strictly ensure the product quality.

10、 The length shall be reasonably determined according to the requirements of the production plan. During sawing, the feeding speed of the sawtooth shall not be too fast to avoid damaging the end. The end must be clamped correctly to remove flash and burr.

11、 The basket loading shall be standardized, including the cushion strip shall be placed reasonably to avoid damaging the profile.

12、 The aging temperature of profile shall be controlled at 190 ± 5 ℃ for 2.5-4 hours, and air cooling shall be carried out after discharging.

Shenzhen jianhuafa Hardware Products Co., Ltd. is a manufacturer of AC / DC fans, aluminum radiators, heat pipe radiators, metal stamping parts and chassis. The company mainly produces aluminum products / heat pipe radiators, equipped with cooling fans and cooling chassis...

Shenzhen jianhuafa Hardware Products Co., Ltd. is a manufacturer of AC / DC fans, aluminum radiators, heat pipe radiators, metal stamping parts and chassis. The company mainly produces aluminum products / heat pipe radiators, equipped with cooling fans and cooling chassis...